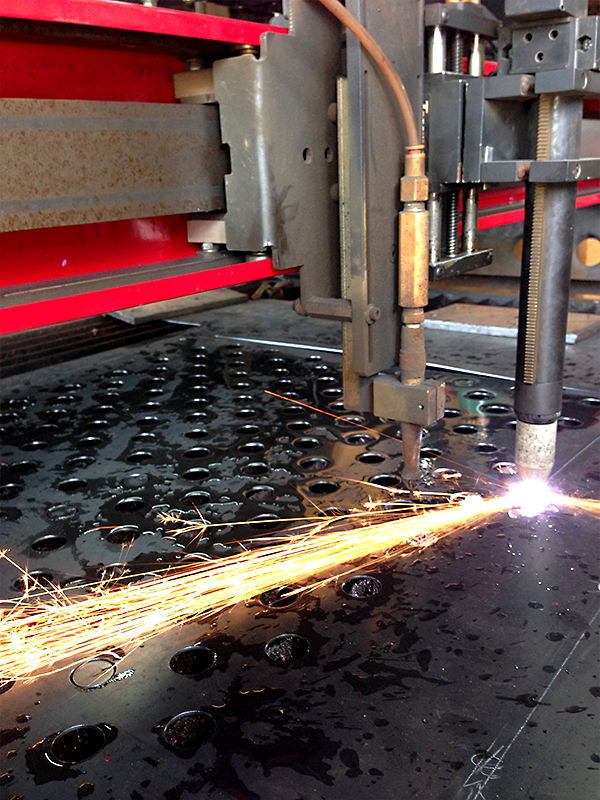

CNC cutting machines help in accomplishing various tasks carried out by traditional craftsmen. People who use cutting machines usually possess the skills required in designing and manufacturing of varied forms of finished products such as furniture, signposts, frames, and a complete range of metal, plastic along with other solid surface objects. Based on the kind of work to be undertaken, the manufacturers who employ these machines will need a particular size and kind of CNC cutting machine.

How to Choose the proper Cutting Machine for the Business?

A quality CNC cutting machine has a four feet by eight feet cutting table, enabling it to satisfactorily handle a typical 4 x 8 plate of metal, wood, plastic, glass, or stone. As could be imagined, a machine whose table is without sufficient length or width will make it essential for the operator to repeatedly reposition his / her material, reducing efficiency considerably. This repositioning is referred to as indexing by the operators of CNC cutting machines.

Selecting the most appropriate CNC cutting machine entails a definite understanding of the type of the cutting to be performed. Although some kinds of manufacture will need merely straight cutting, some others require beveling with the attendant requirements of shaving, trimming, paring and reduction. Thus, selection will entail a precise knowledge of the procedure of manufacture.

Other Factors to Keep in Mind when Selecting a CNC Cutting Machine

It is very important remember that any type of cutting will subject the CNC cutting machine to a certain amount of deterioration. As a manufacturer, you must make sure that your machine includes adequate customer care and maintenance.

Good customer support can be determined by checking for option of spare parts for your machine, as lack of spare parts could require that the electronics of the CNC cutting machine undergo a retrofitting. This would deprive the operator of important production time, diminishing the number of goods that could be sold to the buyer. Thus, good customer support and maintenance ought to be one of many two chief concerns of the manufacturer, the other one being the size of the cutting table.

While this doesn't seem as important as availability of spare parts, it really is just as significant as a large percent of time spent indexing implies less time for actual cutting. This too results in a diminishing in the quantity of finished goods, eventually affecting the business's bottom line adversely.

Financing your CNC Cutting Machine

It would be a good business strategy to look at a lease for an excellent quality cutting machine. Visit website might get your entire expenses financed which may cover your secondary investments, sales tax, freight, installation along with other costs. Lease financing will allow you to buy the tools at current prices however your installments are priced at future costs which are definitely likely to be higher.

Also you get added upgrades that include time. Future investments do not need to be made. You are eligible for tax deductions, in the event that you show your machine costs as operation expenditure. Current values are slashed thus along with tax liabilities. Leasing offers you the chance to remain flexible with your balance sheet.